- HOME >

- Technical Memo >

- The Role and Potential of Low Melting Point Solder Paste in the Pursuit of Carbon Neutrality

The Role and Potential of Low Melting Point Solder Paste in the Pursuit of Carbon Neutrality

2023.11.28

Introduction to Solder Paste Composition and Usage

1.Importance of Carbon Neutrality and Overview of Current Challenges?

1-1.Why is Carbon Neutrality Gaining Attention?

1-2.Global Efforts Toward Carbon Neutrality

2.Overview of Low Melting Point Solder

2-1.Definition and Characteristics of Low Melting Point Solder

2-2.Usage Range and Existing Applications of Low Melting Point Solder**

2-3.Examples of Applications Using Low Melting Point Solder

3.The Relationship Between Carbon Neutrality and Soldering Technology

3-1.Issues of Energy Consumption and CO2 Emissions in Soldering Technology

3-2.Why Low Melting Point Solder Is the Solution for Carbon Neutrality

4.Challenges and Prospects of Low Melting Point Solder

4-1.Challenges of Low Melting Point Solder

4-2.Future Research Challenges for Carbon Neutrality

5.Conclusion

1. Importance of Carbon Neutrality and Overview of Current Challenges

Carbon neutrality refers to the concept of balancing the emissions and absorption of green-house gases such as carbon dioxide and is being recognized as one way to minimize the effects of global warming.

In an effort to reduce energy consumption and carbon dioxide emissions, industries and equipment developers are also being urged to make carbon neutrality a crucial goal. However, traditional manufacturing methods often require high-temperature processing, posing challenges in reducing energy consumption.

In the realm of solder paste, the use of low melting point solder paste, which melts at lower temperatures than conventional products, offers the potential to reduce carbon dioxide emissions and energy consumption. This is why low melting point solder paste is gaining attention as one of the methods to achieve carbon neutrality in the manufacturing sector.

Below, we will provide an overview and the potential of low melting point solder paste, as well as the challenges that lie ahead.

1-1. Why is Carbon Neutrality Gaining Attention?

The rise in the average global temperature is a key factor driving the attention towards carbon neutrality.

As of 2020, the average temperature had increased by approximately 1.1°C compared to the period between the 1850s and 1900s. Without reducing green-house gas emissions, this trend is expected to continue or worsen. Additionally, with the ongoing rise in average temperatures, there is a growing risk of climate-related crises such as intense rainfall and extreme heatwaves.

1-2. Global Efforts Toward Carbon Neutrality

As of 2021, 154 countries have pledged to achieve carbon neutrality by 2050 or by specific deadlines.

While the approaches toward carbon neutrality may differ, there is a general alignment in the direction of policies. Specifically, there is a common thread emphasizing electrification, hydrogenation, and the necessity for significant technological reforms to achieve decarbonization.

For example, developed countries are prioritizing energy policies that emphasize increased use of renewable energy sources while reducing reliance on fossil fuels. The EU has set a goal to achieve “climate neutrality" by balancing green-house gas emissions by 2050. Consequently, environmental regulations are being re-evaluated worldwide, and plans are being devised to achieve carbon neutrality.

2. Overview of Low Melting Point Solder

2-1. Definition and Characteristics of Low Melting Point Solder

The composition of commonly used lead-free solder, such as SAC305 (Sn/3Ag/0.5Cu), has a melting point range of 217 to 219°C.

Solders with a lower melting point include lead solder (Sn/37Pb), which has a melting point of 183°C.

However, due to the adverse effects of lead on human health and the environment, it has been designated as a prohibited substance in various countries, and its use is increasingly regulated. As a result, there is a need for lead-free low melting point solder.

In addition, there is a demand for even lower melting points in the market. Sn-Bi solder, which achieves this, has a significantly lower melting point (around 140°C) compared to SAC305.

Due to this characteristic, soldering at lower temperatures has become possible, allowing for a reduction in reflow temperature settings by 40 to 50°C. Lowering the process temperature not only reduces energy consumption but also mitigates thermal damage to the components. This contributes to reducing process costs and enables the use of heat-sensitive components.

2-2. Usage Range and Existing Applications of Low Melting Point Solder

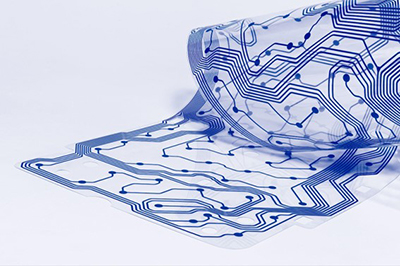

Low melting point solder is particularly suitable for assembling substrates and components that cannot maintain heat resistance with conventional SAC305 solder, including applications in wearable devices, LED assembly, flexible printed circuits (FPCs), and medical devices.

2-3. Examples of Applications Using Low Melting Point Solder

In wearable devices, low melting point solder is chosen to prevent substrate warpage and component damage caused by high temperatures, especially for components that lack the necessary heat resistance capabilities (such as ultra-precision components, plastic components, PET substrates, etc.) or in assembly methods where thermal warping during reflow is a concern.

3. The Relationship Between Carbon Neutrality and Soldering Technology

3-1. Issues of Energy Consumption and CO2 Emissions in Soldering Technology

In conventional soldering technology, the need for high temperature reflow ovens resulted in significant energy consumption and CO2 emissions, posing substantial challenges.

3-2. Why Low Melting Point Solder Is the Solution for Carbon Neutrality

The use of low melting point solder allows for lower reflow oven temperature, leading to substantial reductions in energy consumption and CO2 emissions. This capability is expected to pave the way to carbon neutrality, making the goal more achievable for industries and equipment developers.

4. Challenges and Prospects of Low Melting Point Solder

4-1. Challenges of Low Melting Point Solder

A key challenge with low melting point solder is the issue of joint reliability. Addressing these challenges will be the focus of future research and technological development.Additionally, low melting point solder requires special flux that matches its melting point.

Typically, the inclusion of elements like Bi and In lowers its melting point to below 183°C. However, low-temperature Sn-Bi solder has challenges such as the generation of excessive dross during flow/wave soldering.

Therefore, caution is required when using general low melting point solder.

4-2. Future Research Challenges for Carbon Neutrality

While addressing environmental concerns, developing new materials enabling soldering at even lower temperatures, and the evolution of energy-efficient manufacturing technologies are required.

5. Conclusion

Low melting point solder, essential for heat-sensitive components, holds significant potential for manufacturers and developers in the pursuit of carbon neutrality.

As technology advances and lower melting point solder pastes are developed, further reductions in energy consumption and CO2 emissions can be achieved. Continued research and evolution of this technology are anticipated.

Lastly, we would like to introduce our low melting point solder products.

We offer Sn-Bi solder paste T4AB58-HF360 (Sn 0.4Ag 57.6Bi), as well as dispensing-compatible T4AB58-HF360D solder paste. The melting point of T4AB58-HF360/T4AB58-HF360D is 138-140ºC, allowing for lower temperature settings compared to SAC305, resulting in an approximately 40% reduction in power consumption. Additionally, it achieves reductions in CO2 emissions and energy consumption corresponding to the reduced power usage. It is ideal for use with heat-sensitive components and substrates.

If you are interested in T4AB58-HF360/T4AB58-HF360D, please feel free to contact us.

Inquiry

Product

-

Low melting point solder paste

T4AB58-HF360

Index

Index Domestic Bases

Domestic Bases Overseas Bases

Overseas Bases Sales Network

Sales Network Index

Index Message

Message Description of Business

Description of Business Overview

Overview History

History CSR

CSR