- Home >

- Technical support

Technical Support

Defect Analysis

We observe and analyze provided sample PCB of yours and investigate the cause of defect.

Analysis Items

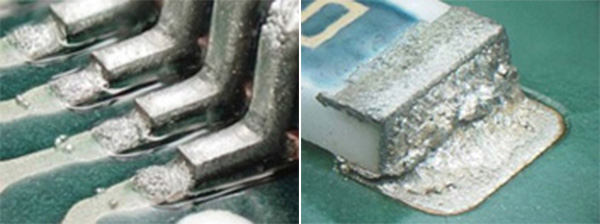

External Observation

- ・Observes Defective Point

- ・Identifies Nature of Defect

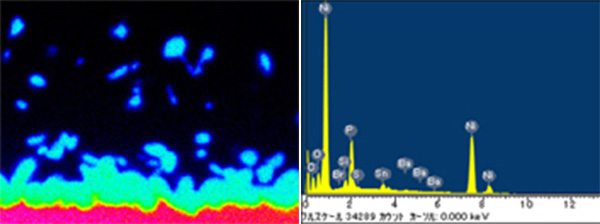

SEM/EDX Analysis

- ・Evaluates Quality of Plating

- ・Identifies Contaminating Element

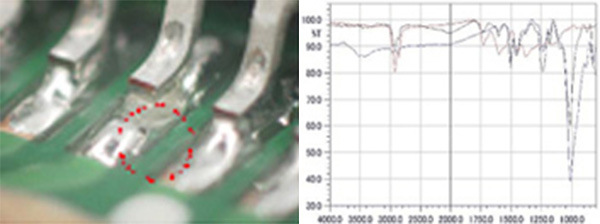

FT-IR Analysis

- ・Analyzes Contaminating Element

- ・Identifies Contaminating Substance

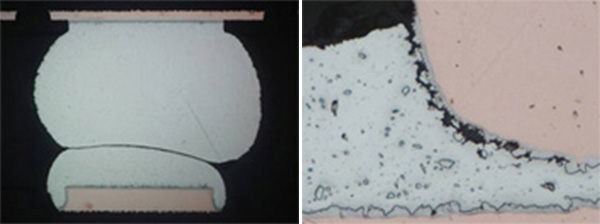

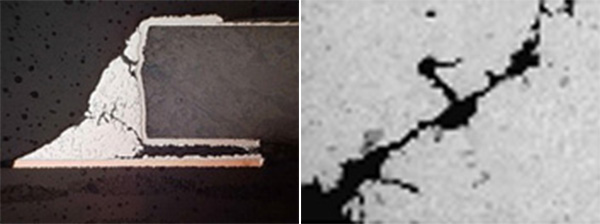

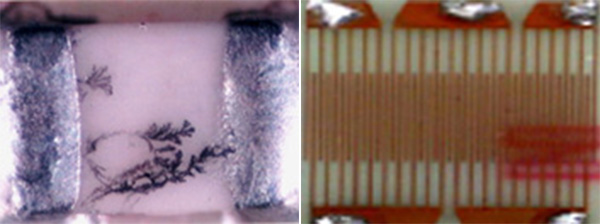

Cross Section Observation

- ・Evaluates IMC

- ・Evaluates Crystalline Structure

- ・Observes Defect (eg. Head-in-Pillow, Clutch, Tombstone)

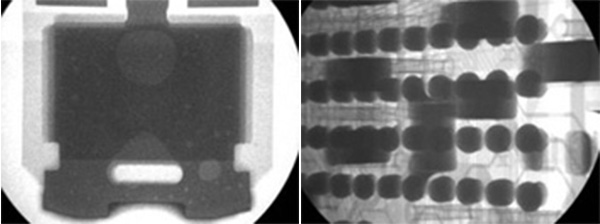

X-ray Analysis

- ・Observes Voiding

- ・Observes Head -in-Pillow Defects

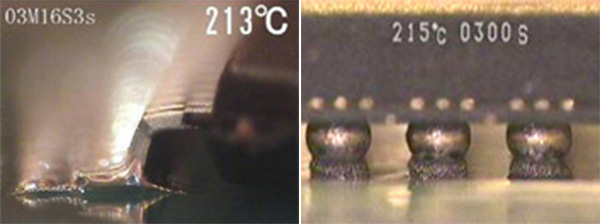

Simulation

- ・Simulates Wetting Behavior

- ・Observe Warpage of Component and Board

- ・Suggests Recommended Reflow Conditions

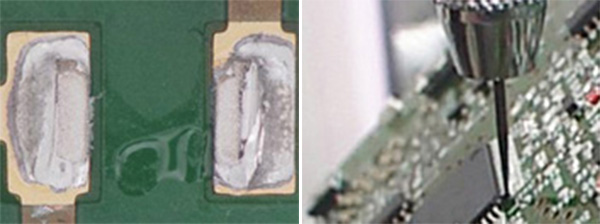

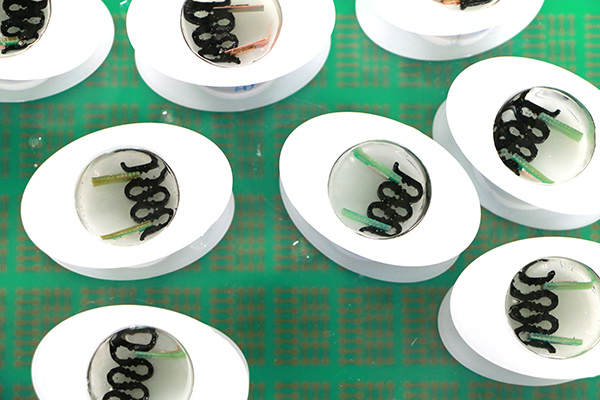

Joint Strength Test

- ・Evaluates Shear Strength

- ・Evaluates Pull Strength

- ・Observes Breakage Mode

Thermal Shock Test

- ・Evaluates Joint Durability

- ・Observes Growth of IMC

SIR Test

- ・Observes Electro-Migration in Thermohygrostat

- ・Evaluates Voltage Applied SIR

- ・Evaluates Drying at Normal Temp

Optimization

We provide assistance for you to achieve the best possible performance in the assembly.

Using conditions may vary from customer to customer, from product to product.

We will investigate and narrow down the optimal print conditions, reflow profile, etc. according to your unique environment

so you can take full advantage of our soldering materials.

Flow to Service Delivery

- 1.Contact

- Give us an e-mail to raise a request for technical support.

- 2.From KOKI

- We will contact you back for further details.

- 3.Analysis / Evaluation

- Koki engineers perform analysis / evaluation based on given conditions.

- 4.Test Report

- Test report will be issued,and sent back to you through Koki rep.

Index

Index Domestic Bases

Domestic Bases Overseas Bases

Overseas Bases Sales Network

Sales Network Index

Index Message

Message Description of Business

Description of Business Overview

Overview History

History CSR

CSR